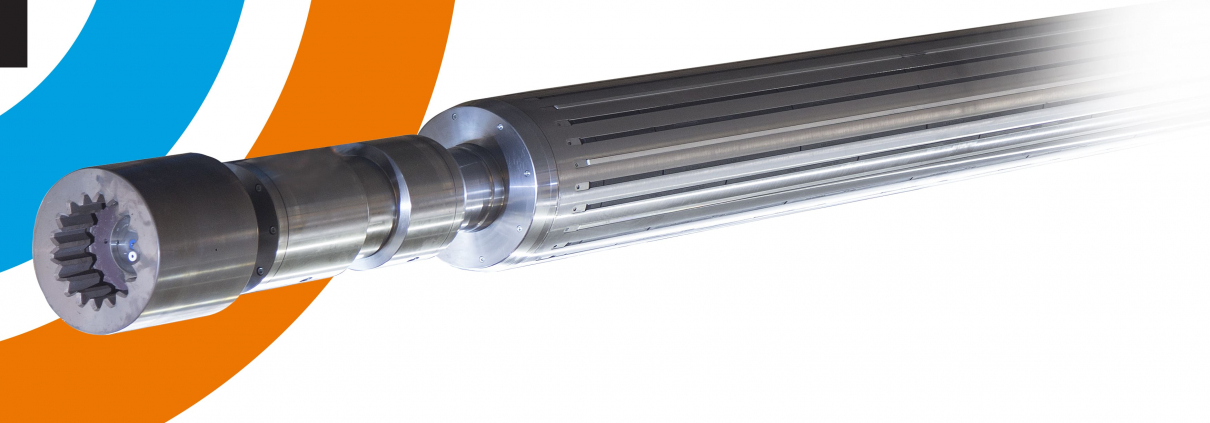

The 640 / PQL model is the expansion shaft preferred by machine manufacturers for its use in the production of jumbo rolls of paper and tissue on cores.

Dozens or even hundreds of heavy and expensive expandable shafts currently used to wrap, store or transport reels are not needed.

Only from 3 to 6 640 / PQL shafts are needed to run non-stop.

On today’s high-speed paper machines, it is essential to minimize vibrations and unbalance. Our technology can centre the core on the shaft diameter before locking it. The metal centring ledges work in combination with the rubber gripping ledges: the metal ledges are designed to expand first, centring the core on the shaft diameter; subsequently, the rubber ones are raised to block it.

This allows the shafts to work quickly, without hitches or vibrations at higher speeds. All shafts are dynamically balanced up to grade G-1.6.